With great joy and justified pride, we are pleased to announce: Together with our customer RHI Magnesita, we have converted the world’s first bell kiln in the refractory industry to run on hydrogen.

In Marktredwitz, the kiln was successfully heated to up to 1,650 degrees Celsius with pure hydrogen

— a milestone for sustainable industrial processes.

The specially equipped kiln can be operated flexibly with pure hydrogen, natural gas, or a combination of both—an essential advantage for future industrial applications.

The conversion of this high-temperature kiln not only marks a technical breakthrough but also a pioneering step toward climate-friendly production.

The hydrogen used comes directly from the nearby electrolysis plant in Wunsiedel, which is powered by green electricity.

This project impressively demonstrates what is possible when a spirit of innovation, technical expertise, and sustainability ambitions go hand in hand.

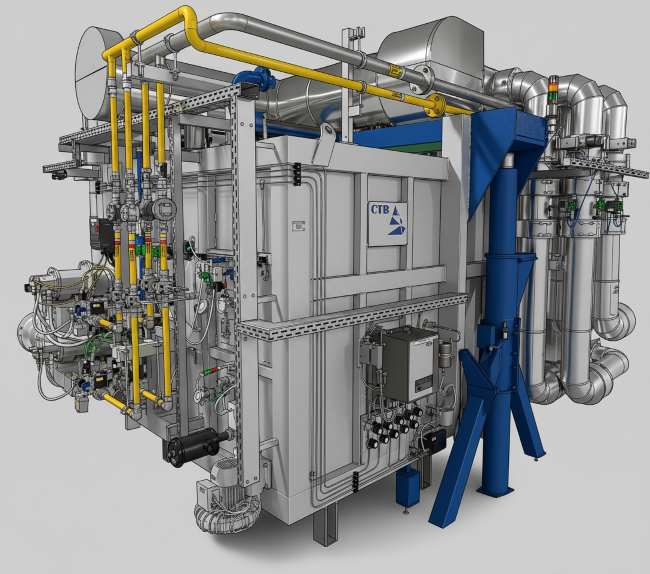

Before the world’s first hydrogen bell kiln became a reality, a precise digital twin was created: our 3D design served as the basis for planning, sizing, and aligning all relevant components. The detailed visualization made it possible to efficiently coordinate complex piping, safety aspects, and the integration of state-of-the-art burner technology. This virtual model was not only a planning tool but also a communication tool among all project stakeholders—from engineering to on-site execution. Especially given the compact design and tight spatial constraints of the legacy installation, this end-to-end digitalization was a decisive success factor.

With the conversion of a decades‑old natural gas hood kiln at RHI Magnesita in Marktredwitz,

CTB has realized a truly unique project: the world’s first industrially usable hydrogen hood kiln in the refractory industry.

The goal was to transform an existing facility into a state‑of‑the‑art research kiln –

equipped with newly developed burner, control, and safety technology that not only enables full operation with hydrogen,

but also retains the option to operate with natural gas.

The result is a flexible, high‑performance, and future‑oriented kiln.

The new kiln is currently being used to study the effects of hydrogen‑based combustion on products and linings. With its flexible fuel control, high temperature performance, and improved heat transfer, it provides ideal conditions for practice‑oriented research. The increased radiation resulting from hydrogen combustion offers additional optimization potential – while at the same time requiring careful attention to the risk of local overheating.

Tomorrows Kiln Technology Today